We’re proud to use innovation not just for progress, but for lasting impact — maximising yield, reducing waste, and creating high-performance timber with a deeper purpose.

Our process unlocks the potential of underutilised timber — from low-grade logs to juvenile material — transforming it into premium hardwoods with the look, feel, and performance of 100-year-old trees.

All in just one day.

This world-first Australian innovation was developed by 3RT in collaboration with world-leading experts at Flinders University, Henkel, and Bosch — combining cutting-edge science, engineering, and technology.

See the technology in action

From low-value wood to premium timber

Not only do we work with what the industry often dismisses as low-grade, but we process these logs in a way that recovers up to twice as much usable timber — thanks to rotary peeling, a method that leaves traditional milling in the dust (quite literally!)

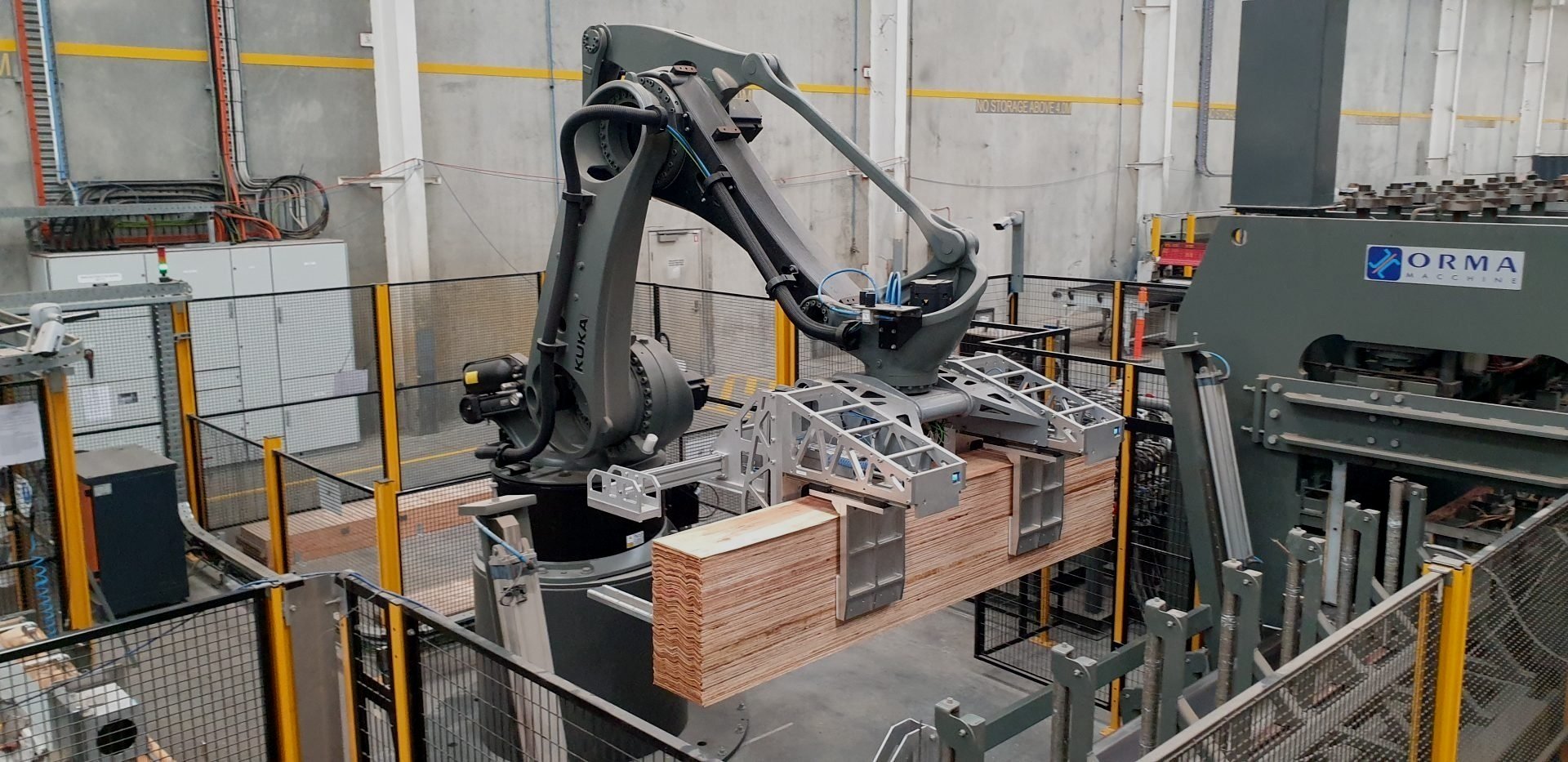

Then the real magic happens. Using advanced robotics and biomimicry, we reassemble this high-yield material into large, uniform billets — our “square trees” — engineered for performance, designed for creativity, and made to do more with less.

It’s not just timber. It’s timber, reimagined — unlocking new possibilities while making the absolute most of every resource.

Biomimicking nature

in one day

At the core of our process is a water-based “nano glue” that replicates the wonders of lignin — the natural compound that holds trees together. Applied to wood fibers, it locks those fibers together, creating the strength, beauty, and character of century-old wood in a fraction of the time.

And there’s no harmful chemicals or formaldehyde involved.

Our process is fast.

Really fast.

Our process is so efficient, a single machine can produce 300kg of timber every 15 minutes.

Thanks to precision engineering, each log is consistently dimensioned at 2500mm x 500mm x 250mm, unlocking maximum output and endless possibilities. From there, we can tailor the timber to meet the unique needs of our clients — cutting and finishing it to suit any application.

And with the ability to tap into juvenile resources, we unlock valuable timber decades before it would traditionally reach maturity, giving us more of what we need, faster.

Same, same but different.

While our process guarantees precision and consistency, every block we produce is one-of-a-kind, showcasing the natural beauty and unique character of wood.

With a variety of species and two grain cut options, we’re ready to find the perfect match for your project — tailored to your needs, every time.