From low-value pulpwood to premium timber.

We are redefining sustainable timber production.

Ready to learn something new?

Keep on reading…

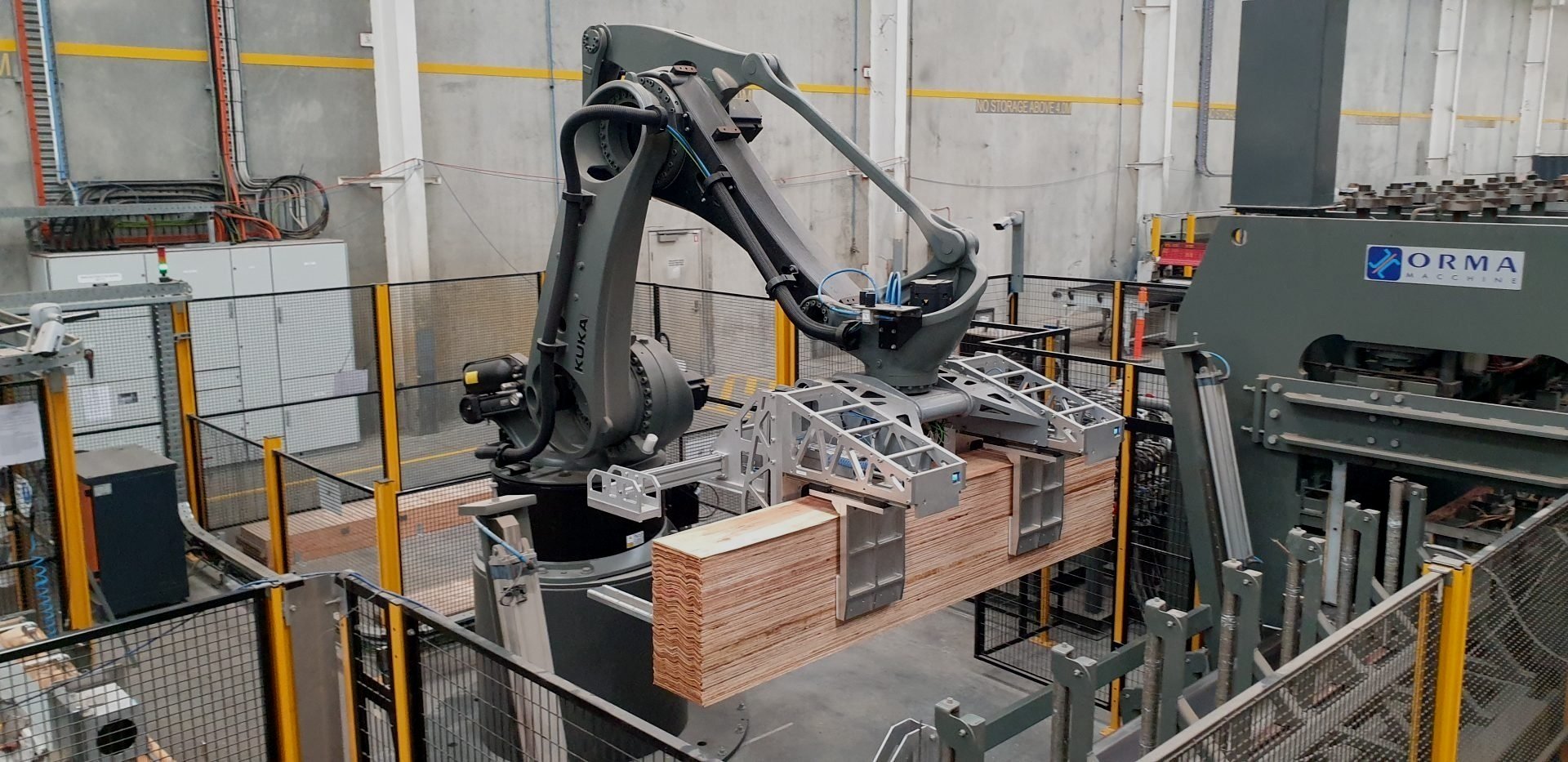

Wood made by robots

We grow trees in a machine. In one day.

Right here in Australia.

Our process uses a world-first Australian technology developed by 3RT in partnership with Flinders University, Henkel, and Bosch.

We transform low-value pulp grade wood resources into premium hardwoods with the look, feel and properties of century-old trees.

Our timber offers an unprecedented solution to the increasing demand for low-carbon, toxin-free, and renewable building materials, all while safeguarding our native forests and vital biodiversity areas.

Biomimicking nature

in one day

At the heart of this technology is a patented process using a water-based “nano glue” that biomimics the properties of wood’s natural lignin, a complex organic compound produced by trees.

This gives our timber the same structure and remarkable properties as mature trees, in a fraction of the time.

Rethinking our wood supply

“If we do not rethink the supply chain and find a way to produce timber in large quantities, sustainably, and with consideration for future generations, it will cease to be a viable core building material.”

What makes us so different? Rather than relying on mature trees from old-growth and native forests, our timber is crafted using abundant juvenile pulp resources.

Did you know that Australia alone produces on average 16 million m3 of pulpwood every year? In fact, every year 49% of all trees logged from our forests end up classed as low-value pulp logs.

Because of their inferior value, these trees would traditionally be converted into wood chips and exported. They may be low value to others, but to us, they are PERFECT!

We can divert those resources and turn them into premium hardwoods that are:

100% natural

100% recyclable

appearance-grade

chemicals & toxin-free

Essentially, we are pioneering a way of producing timber that not only maximise the utilisation of our forest resources, but also contribute to safeguarding our native forests by removing the reliance on old-growth forest to supply the material required to meet the increasing timber demand.

Chain of Custody certified

Chain of Custody certification is our guarantee that every step of our product journey—from forest to final product—is tracked, transparent, and responsibly managed.

It sets us apart by providing our customers with confidence that they’re choosing products that actively support forest conservation and responsible forestry practices.

Our process is fast.

Really fast.

Our process is so efficient that we can produce one cubic meter of timber in less than an hour.

Our finished logs are dimensionally consistent at 2500mm x 500mm x 250mm. This allows for maximum output and endless applications. Depending on our clients needs, the billets are then cut and finished as required.

Same, same but different

Whilst our process ensures that billets are consistent in dimension, every single block we produce is unique and highlights the beauty and characteristics of natural wood.

With several wood species to choose from and different cut options to suit every style, our timbers are the perfect material for architects, builders, carpenters and designers to include in their projects.